What Are You Looking For?

Coolant distribution units (CDUs) cool, distribute, and regulate fluid within a liquid cooling system. By optimizing both individual components and how they work together, Boyd builds efficient, high capacity CDUs in dense volumes.

Applications include performance computing, AI applications, machine learning, GPT, energy storage, and more.

Push System Performance

Push System Performance

Functionality and Versatility

Functionality and Versatility

High-Density AI Workloads

High-Density AI Workloads

CDUs offer unparalleled flexibility, with six standard models and custom OEM configurations that scale to support up to 2.3 MW of IT load.

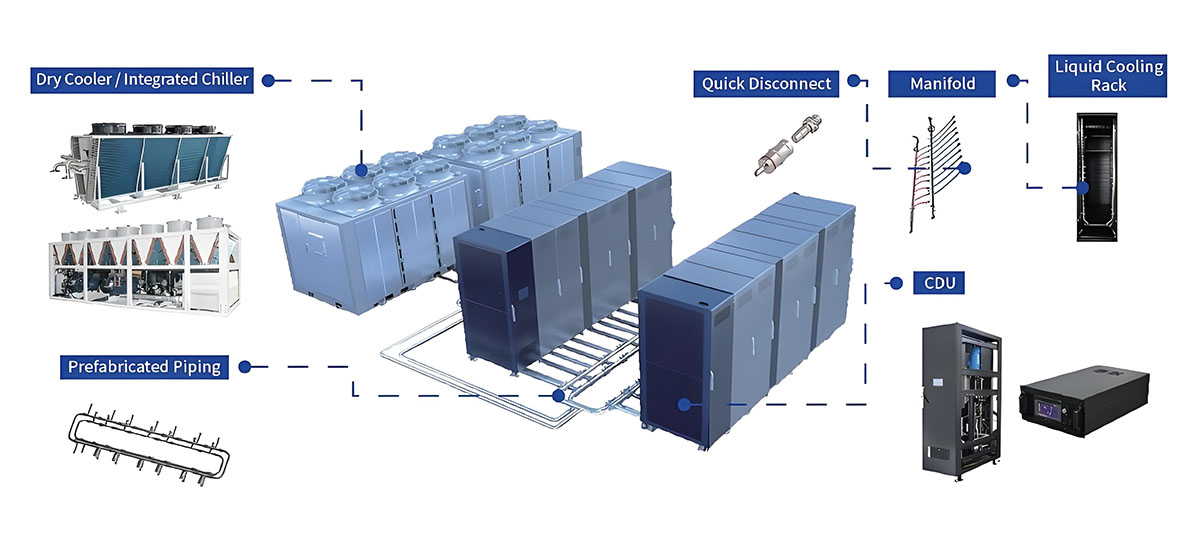

COLD PLATE LIQUID COOLING SOLUTION

Coolnet focuses on the research and development of data center cooling products, offering a full serial of products from liquid-cooling Rack, CDU, manifold, immersion tanks, prefabricated piping, and primary side cooling sources to meet the cooling needs of various data centers. The integrated design of dry coolers and supplementary cooling units, with air-cooled modules and liquid-cooled modules sharing a set of cold water trays, which could reduces costs, saves space, and facilitates on-site installation.

COOLANT DISTRIBUTION UNITS (CDU)

Highest density coolant distribution units (CDU) are engineered to meet the most demanding direct liquid cooling requirements for artificial intelligence (AI), high-performance computing (HPC), and enterprise computing applications. Coolnet’s CDUs deliver exceptional performance, density, efficiency and reliability for data centers with or without facility water infrastructure.

FLEXIBILITY AND SPACE-SAVING

In a server cooling system, integrated CDUs enable greater processing power density meaning more servers can fit in each data center rack. Integrate CDUs directly into facility water or facility-level cooling systems for direct rack server cooling or design self-contained cooling that offers the next level of flexibility for liquid cooled servers.

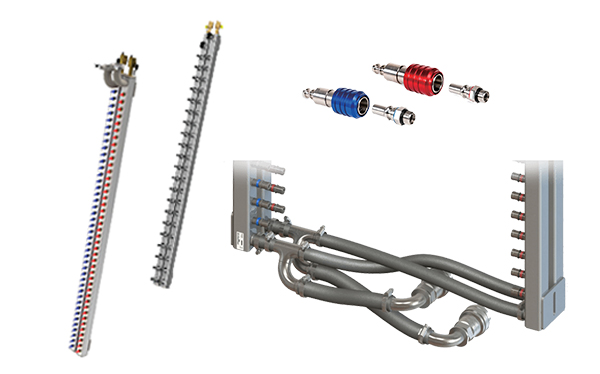

MANIFOLDS & CONNECTORS

Manifolds are made of reliable stainless steel for rugged durability.

To ensure uniform liquid flow rate, a liquid distribution structure is set at the outlet;

Quick connector design reduces air entry;

By adjusting the spacing and hole position, the coolant flow and heat dissipation are uniform.

Rack Manifolds are organized for a manual connection at the front or back of the rack, are flexible and can be arranged vertically or horizontally within a rack.

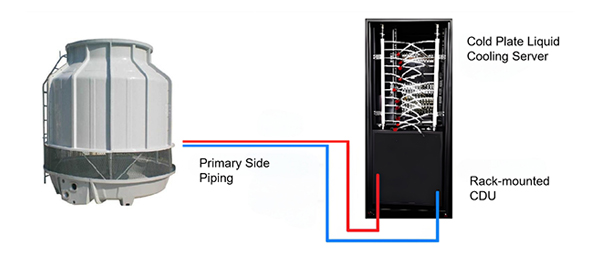

HIGH IMPACT COOLING WITH FACILITY WATER

Liquid to Liquid CDUs require facility water to remove heat from rack and row equipment but come with a battery of benefits to offset added system complexity. Fully liquid cooled data centers maximize energy efficiency from the higher heat capacity of liquid throughout the full data center.

DRY COOLER

The heat exchanger tubes are made of SUS304 material, which is high strength and corrosion resistant, suitable for various heat transfer media.

All materials in contact with the fluid are SUS304, ensuring safety and reliability.

The heat exchanger fins are made of anti-corrosion coated aluminum fins, which offer good heat transfer and are corrosion resistant.

EC axial flow fans with 10% to 100% stepless speed control for precise temperature regulation.

INTEGRATED CHILLER

The temperature difference between the water outlet of the dry cooler and the ambient temperature can be around 7~8°C.

When the water outlet temperature of the dry cooler is 40℃ and the ambient temperature is below 32°C only the dry cooler operates, making full use of the natural cold source.

When the temperature exceeds 32℃ during high-temperature periods in the summer, the high evaporation temperature chilled water unit is activated to supplement the cooling capacity.